3 others

Why focus on infrastructure

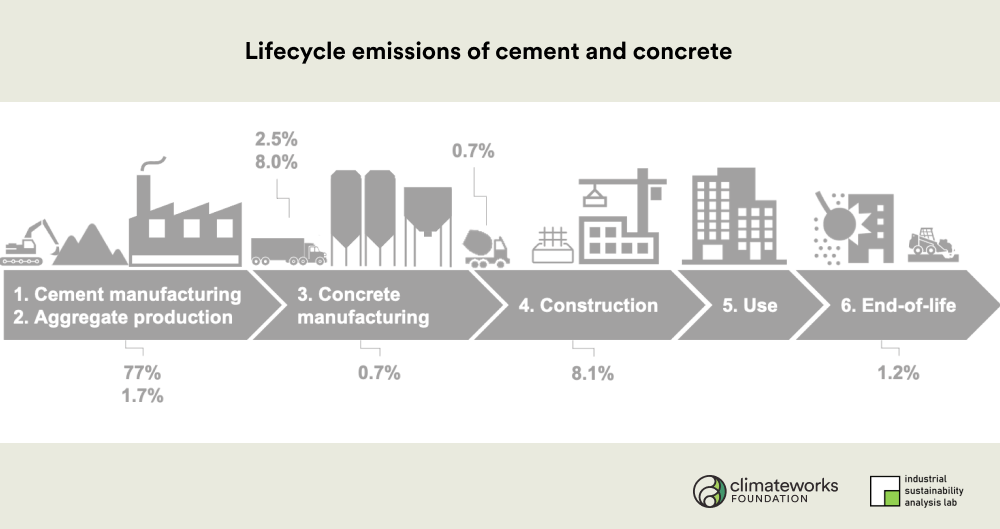

Concrete is the world’s most used building material, and demand for it continues to rise globally. As the world rapidly approaches 1.5° C of warming, the cement and concrete cycle, which represents roughly one-tenth of the global total greenhouse gas emissions, cannot continue business as usual. A cradle-to-cradle decarbonization pathway in this sector is particularly important today, as the U.S. Congress is considering a new infrastructure bill as part of the Biden administration’s “Build Back Better” agenda. According to new research from Northwestern University, supported by ClimateWorks Foundation, there is an opportunity to align that rebuilding with domestic and international climate goals.

The new report, “Decarbonizing concrete: Deep decarbonization pathways for the cement and concrete cycle in the United States, India, and China,” shows in greater detail than ever before that there are multiple pathways to get the cement and concrete industry to net-zero emissions by midcentury by ramping up conventional mitigation approaches, increasing research and development, and reducing demand through measures like lean construction and substituting engineered timber building materials for concrete. Governments and companies equipped with this system-wide understanding can set more ambitious targets for economy-wide decarbonization.

What decarbonizing cement by mid-century would look like

One clear conclusion of the report is that there is no single solution, but rather a range of changes that will be necessary. The report identifies three categories of decarbonization, which is then broken down into seven approaches and 30 specific levers.

Some of these approaches are technologically mature and exist at the commercial scale, such as improving energy efficiency at cement plants and certain carbon utilization technologies. Others exist at pilot-scale and require more research and investments to improve cost and performance, such as lower-carbon cement chemistries. Options like using materials more efficiently and substituting timber engineered for greater strength and fire-resistance for concrete requires more consumer awareness and widespread availability.

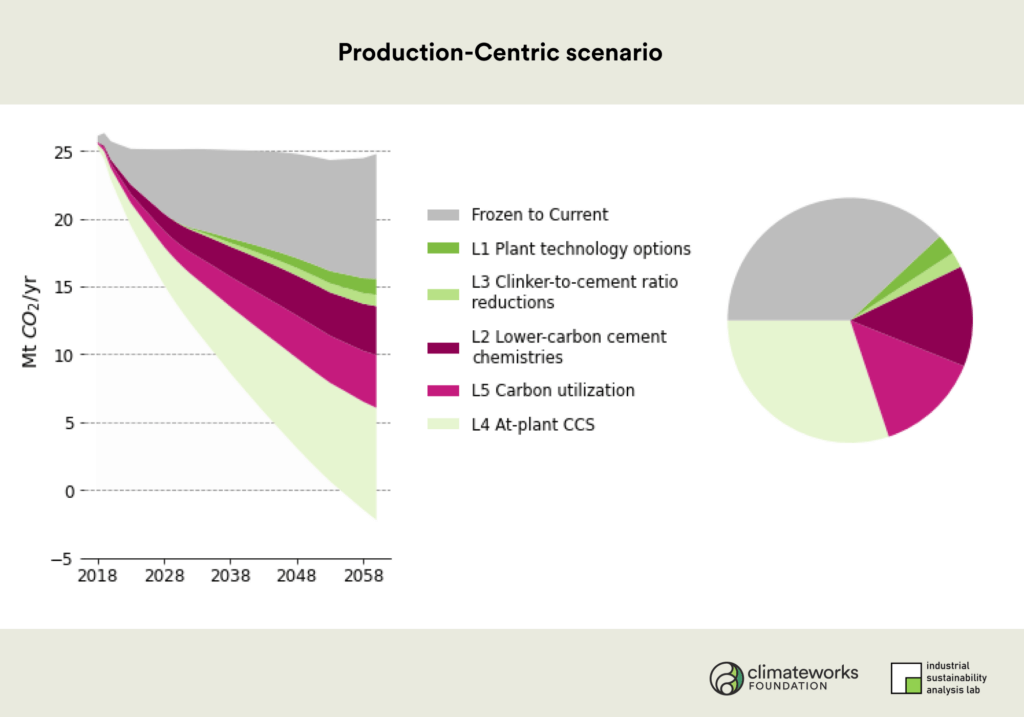

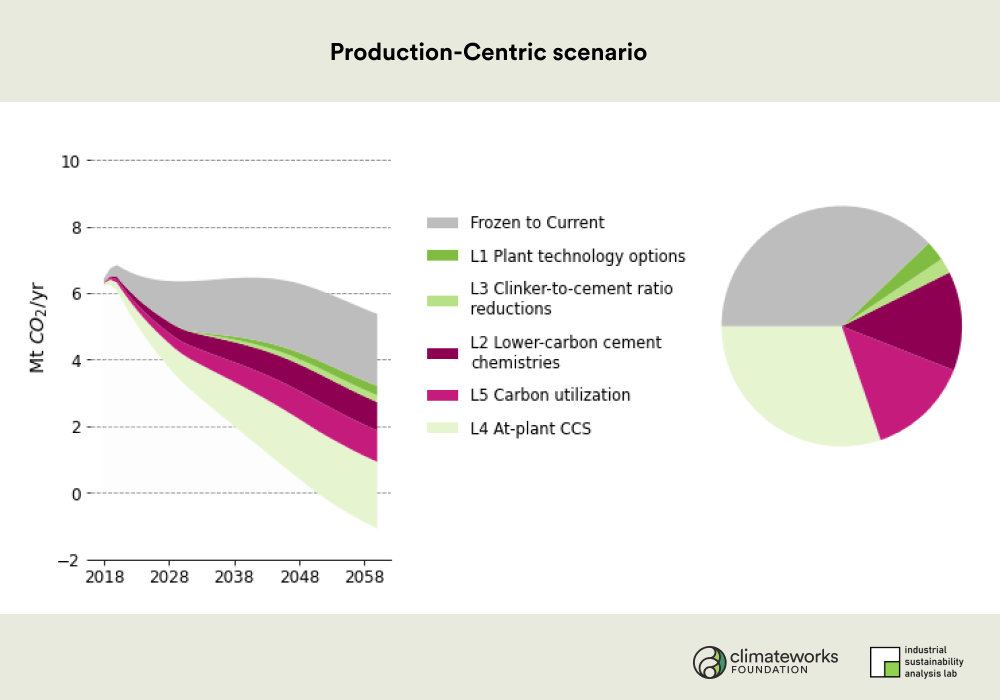

The research examines two plausible scenarios of how to decarbonize cement and concrete across its entire life cycle. The Production-Centric scenario explores ways to reach net-zero emissions solely through measures that reduce the carbon intensity of cement and concrete production. This is in line with the traditional business models and thus relies on action taken primarily by the cement and concrete industries. This scenario shows that technological improvements to cement and concrete manufacturing processes can dramatically decrease the carbon intensity of cement through the use of lower-carbon cement chemistries, switching to cleaner energy sources, capturing CO2 emissions at the plant, and storing CO2 in the cement and concrete. However, some of these options may increase the cost of cement and concrete considerably and some require additional research and development in order to improve commercial viability.

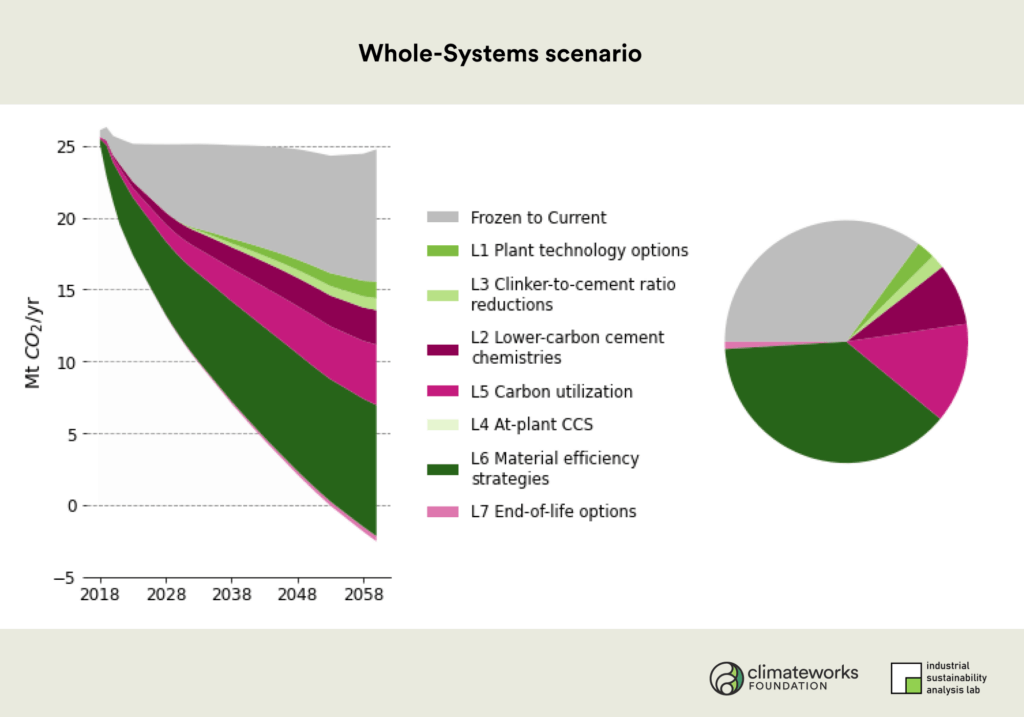

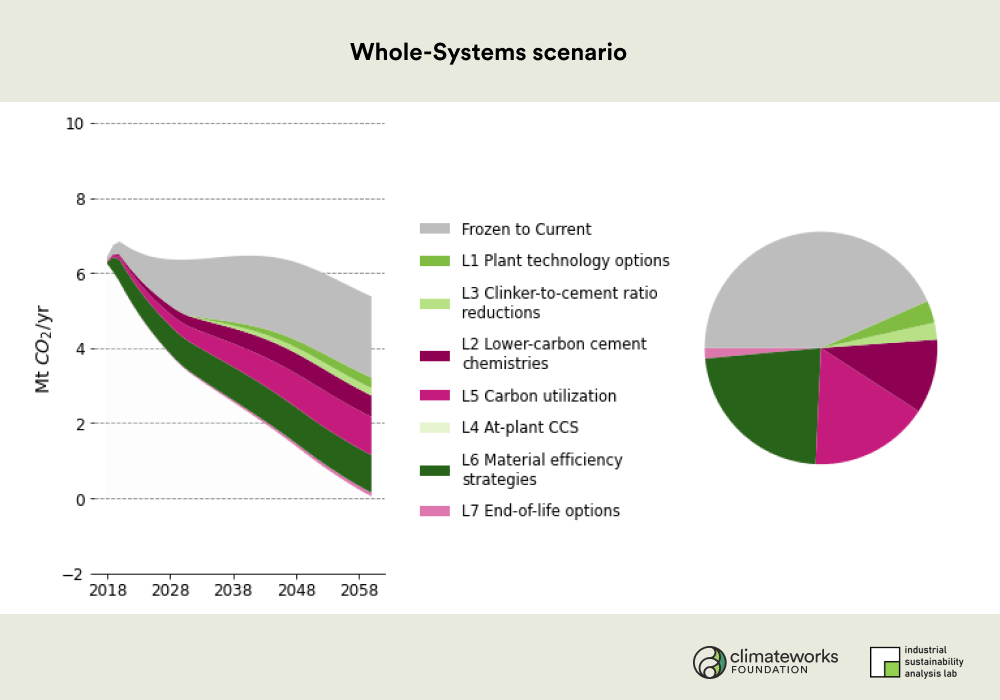

The alternative Whole-Systems scenario explores a wider portfolio of levers, with emphasis on reducing demand for cement and concrete. This scenario still requires a substantial amount of technological improvement, along with actions by a broad array of stakeholders to use cement and concrete much more efficiently. The CO2 emission savings come from the combined effects of lower production emissions, reduced concrete demand, and CO2 stored in building materials. The challenge here is the need to embrace new business models, the need for rapid development of enabling policy regimes, and the need to mobilize a larger group of stakeholders from architects to the general public.

Decarbonization potential of concrete in U.S. buildings across seven levers

Decarbonization potential of concrete in U.S. roads across seven levers

Everybody has a part to play

Policymakers can make these pathways possible by increasing investments in R&D, providing technology deployment incentives, changing construction codes and standards, and encouraging public-private partnerships to develop, demonstrate, and deploy key technology innovations. Governments can also use public procurement to create markets for both low-emissions concrete and concrete alternatives through policies like Buy Clean.

Philanthropy can also play a key role. It can support groups that inform policymakers about the policy options available. It can help catalyze the use of low-emissions alternatives in the private sector by creating consumer awareness and voluntary certifications for sustainable building materials. It can generate case studies and knowledge-sharing networks to reduce perceived risk and accelerate best practices in design and built environment policies, and develop targeted roadmaps. New databases on markets, as well as the costs and savings of various initiatives, can help chart the course at the country level.

The public and private sectors need to get serious about decarbonizing the cement and concrete cycle now — there is no time to waste. Different countries will encounter different challenges and opportunities. Countries with established stocks of buildings and infrastructure, like the U.S., will use different combinations of approaches than countries like India that still need to build out their stock. This research has shown that we have enough tools to meet these challenges, and we need to get started now. Governments should feel confident setting ambitious, long-term net-zero emissions targets, and should implement them through near-term action. In the U.S., federal procurement standards and other supports for concrete and cement cycle decarbonization in the upcoming infrastructure bill, as well as its updated Nationally Determined Contribution to the Paris Agreement, are important opportunities to take the first steps down this path.

Learn more

Read the full report here, or contact us to learn more about how to decarbonize the cement and concrete industry.