Around the world, the materials that make modern life possible — cement, steel, and chemicals — also drive nearly one-third of global greenhouse gas emissions. For decades, these industries were considered nearly impossible to decarbonize (or, “too hard to abate”). But a new generation of scientists, engineers, funders, and entrepreneurs is reimagining how the world builds its foundations — cutting carbon at its source while improving the durability of essential materials, saving costs over time, and creating jobs, markets, and inclusive growth.

Reinventing cement from the ground up

One of the most promising breakthroughs is emerging from a simple, local material: clay.

Limestone Calcined Clay Cement (LC³), developed through international efforts, cuts cement emissions by 40 percent or more while lowering production costs and energy use. Made from abundant clay, LC³ is cleaner, cheaper, and easier to produce locally — an important breakthrough especially for fast-growing economies with soaring demand for infrastructure.

LC³ isn’t just a cleaner form of cement — it achieves strength comparable to ordinary Portland cement, while offering improved durability and lifespan, making it ideal for infrastructure projects like roads and bridges. Its greater durability means lower maintenance costs and fewer disruptions, while its cost-effective production strengthens local industries, saves taxpayer money, and creates jobs — proving that climate solutions can also drive growth and prosperity.

LC³ began with a joint discovery by two scientists, one studying clay quarries in Cuba, and one working in a Swiss lab. In the 1990s, Professor Fernando Martirena at the Universidad Central “Marta Abreu” de Las Villas in Cuba and Dr. Karen Scrivener at Switzerland’s École Polytechnique Fédérale de Lausanne developed a method to replace much of the clinker — the most carbon-intensive part of cement — with a blend of limestone and calcined clay, maintaining strength and improving durability.

That breakthrough became the LC³ Project, a group of researchers, universities, and producers working to make low-carbon materials accessible and affordable worldwide. The project has evolved into a global network of LC³ technical centers that connect scientists, engineers, and manufacturers eager to apply the innovation where it’s needed most.

From lab to large-scale production

One of the first LC³ technical centers was founded at the Indian Institute of Technology Delhi, where Dr. Shashank Bishnoi’s team adapted the LC³ formula to local materials and trained engineers to scale production. Within a few years, the innovation moved beyond pilot plants to commercial use in regions across the country.

LC³ has also taken off in Africa, the world’s fastest-urbanizing region. How Africa’s new cities are built will determine whether its growth fuels climate resilience — or amplifies risk.

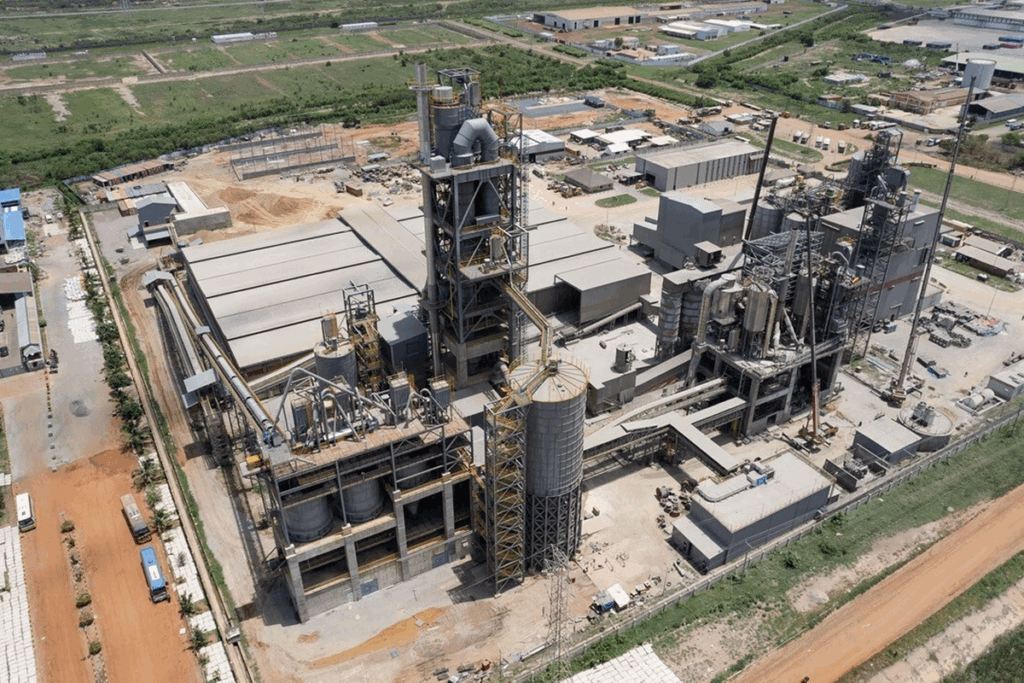

Opened in 2025, CBI Ghana is the world’s largest LC3 plant, driving local growth and creating 300+ jobs in Accra.

In Kenya, Professor Joseph Marangu leads the LC³ Africa Technical Resource Centre, working with producers, researchers, and entrepreneurs to localize LC³ production. His work at Meru University of Science and Technology starts with mapping clay deposits near existing cement plants, and aims to strengthen domestic industries, shorten supply chains, and create good local jobs in sourcing, transport, and manufacturing.

“The opportunity here is enormous,” Marangu says. “We have the materials, the expertise, and the chance to build prosperity without locking in pollution. LC³ allows us to create jobs and build clean infrastructure without sending our hard currency abroad.”

Today, there are 16 full commercial-scale LC³ plants operating in India, Colombia, Ghana, and France, with another 11 in development or under construction across Africa, Asia, Europe, and North America.

These deployments prove LC³ is market-ready — enabling inclusive, locally-led growth while delivering rapid payback periods and substantial operational savings that make low-carbon cement both practical and profitable today.

Accelerating the industrial transition

To scale breakthroughs like LC³ and accelerate this industrial transformation, ClimateWorks helped launch the Global Industry Hub in February 2025, a $200 million funder collaborative uniting philanthropies, technical experts, and industry leaders to tackle emissions at their source.

The Hub channels patient, risk-tolerant capital into technologies that are transforming steel, cement, and chemicals, an approach known as source investing.

“We’re not just cutting emissions — we’re building new markets at the source, where innovation meets industry,” says CEO Hyoeun Jenny Kim.

But perhaps the Hub’s greatest innovation is trust: acting as an honest broker and mission-aligned convener, it connects funders, innovators, producers, and civil society, building the trust and alignment needed to accelerate change. Through pooled funding, technical capacity, and support for civil society, the Hub strengthens the enabling environment for transformation. It helps early solutions scale by de-risking innovation and ensuring that capital and capacity flow to rapidly-industrializing regions, local manufacturing clusters, and the communities building the economies of the future.

Building the foundations of a low-carbon future

LC³’s journey from the clay quarries of Cuba to full-scale industrial plants on four continents shows what’s possible when ingenuity and catalytic capital come together.

The Global Industry Hub aims to make that transformation durable by working with innovators across continents to ensure that our industrial future is low-carbon, inclusive, and built to last.